Product info ThermEx Thermal Maintenance System (TE)

The ThermEx Thermal Maintenance System is used in several piping applications to keep the process flowing, to prevent vapor condensation on the pipe wall, and heating-up or cool-down the process.

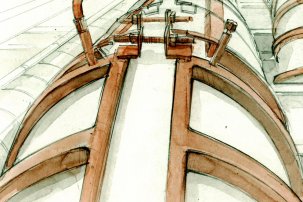

The ThermEx Thermal Maintenance System is used as external heating system on vessels, drums and tanks in cases where contamination from internal coil leaks cannot be tolerated and/or the wall temperature uniformity is critical to prevent condensation and corrosion.

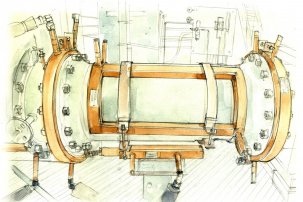

The ThermEx Thermal Maintenance System is made from carbon steel boiler tubing, deformed to a rectangular section mating on one large side the radius of the pipe to be heated. Through these TE elements steam, hot oil or glycol water is conveyed as heating medium. The heated TE elements will transfer the heat at first to the pipe/vessel wall and secondly to the process medium. The shape of the rectangular sections provides a wide heating surface to its component guaranteeing an optimal heat transfer. The use of heat transfer mastic between TE-system and wall will avoid any air-gap and additionally will act as corrosion barrier. Constant and equal heating will avoid cold or hot spots.

The combination of its cost advantage over jacketed piping and its thermal and reliability advantages over tube tracing make it an attractive thermal maintenance solution for most processes.